Ceramic Fiber Modules

A ceramic fiber module is a pre-formed, rigid unit made from high-temperature-resistant ceramic fiber materials. These modules are typically used in thermal insulation applications where heat resistance, low thermal conductivity, and durability are required. Ceramic fiber modules are designed to be easily installed in furnaces, kilns, and other high-temperature environments, where they provide thermal insulation and protect surfaces from extreme heat.

These modules are made by folding a ceramic fiber blanket or mat into a compact, pre-formed shape. The fold provides a flexible and compact form that can be expanded or installed easily in specific spaces.

Nature's Symphony

Nature's Symphony

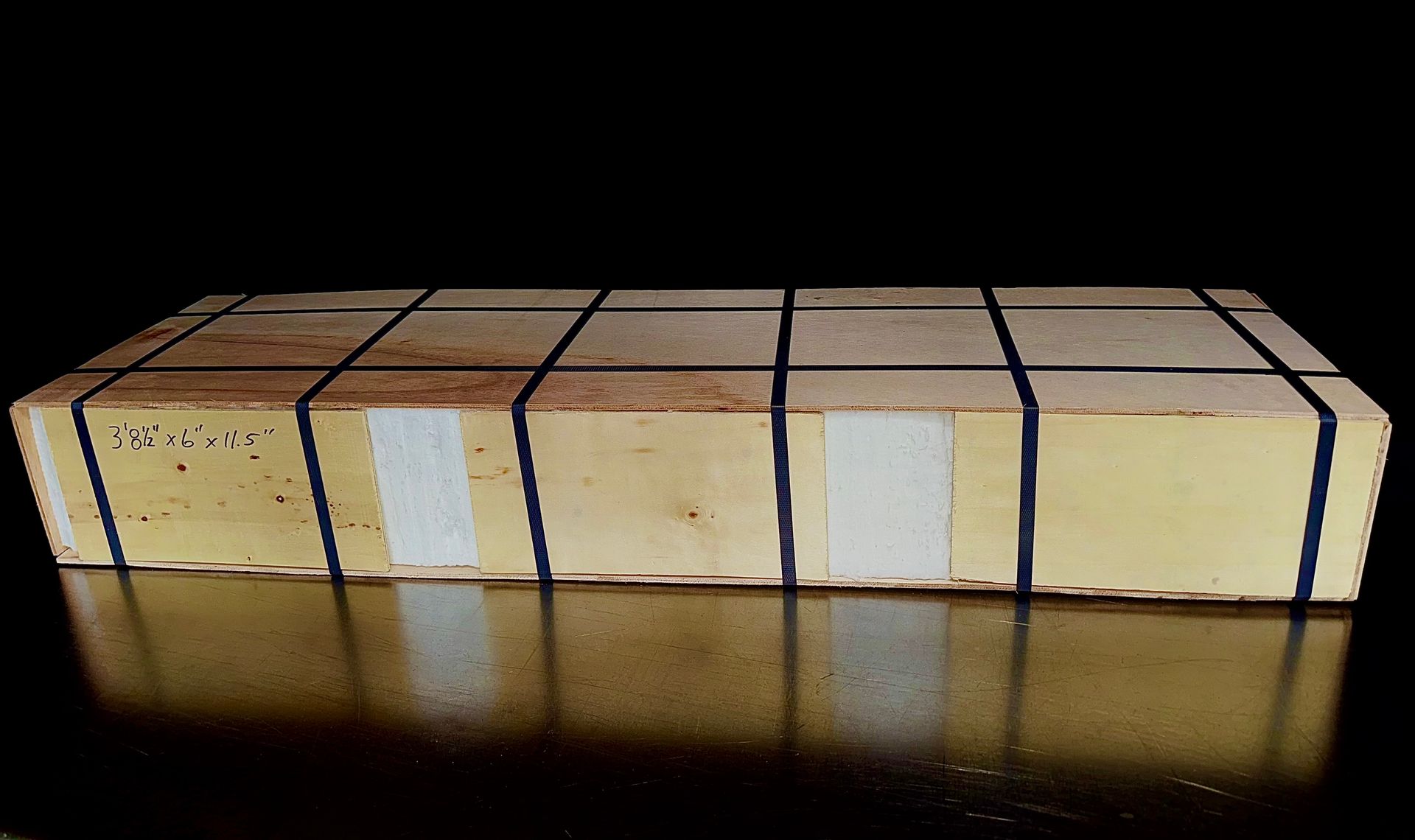

These are created by stacking individual layers of ceramic fiber material on top of one another to form a modular unit. The layers are typically arranged with the fibers aligned for optimal insulation properties.

Ceramic fiber insulation module that has a rounded, curved edge or "bullnose" shape, typically designed to fit around corners, edges, or curved surfaces in high-temperature applications.

Nature's Symphony

Nature's Symphony

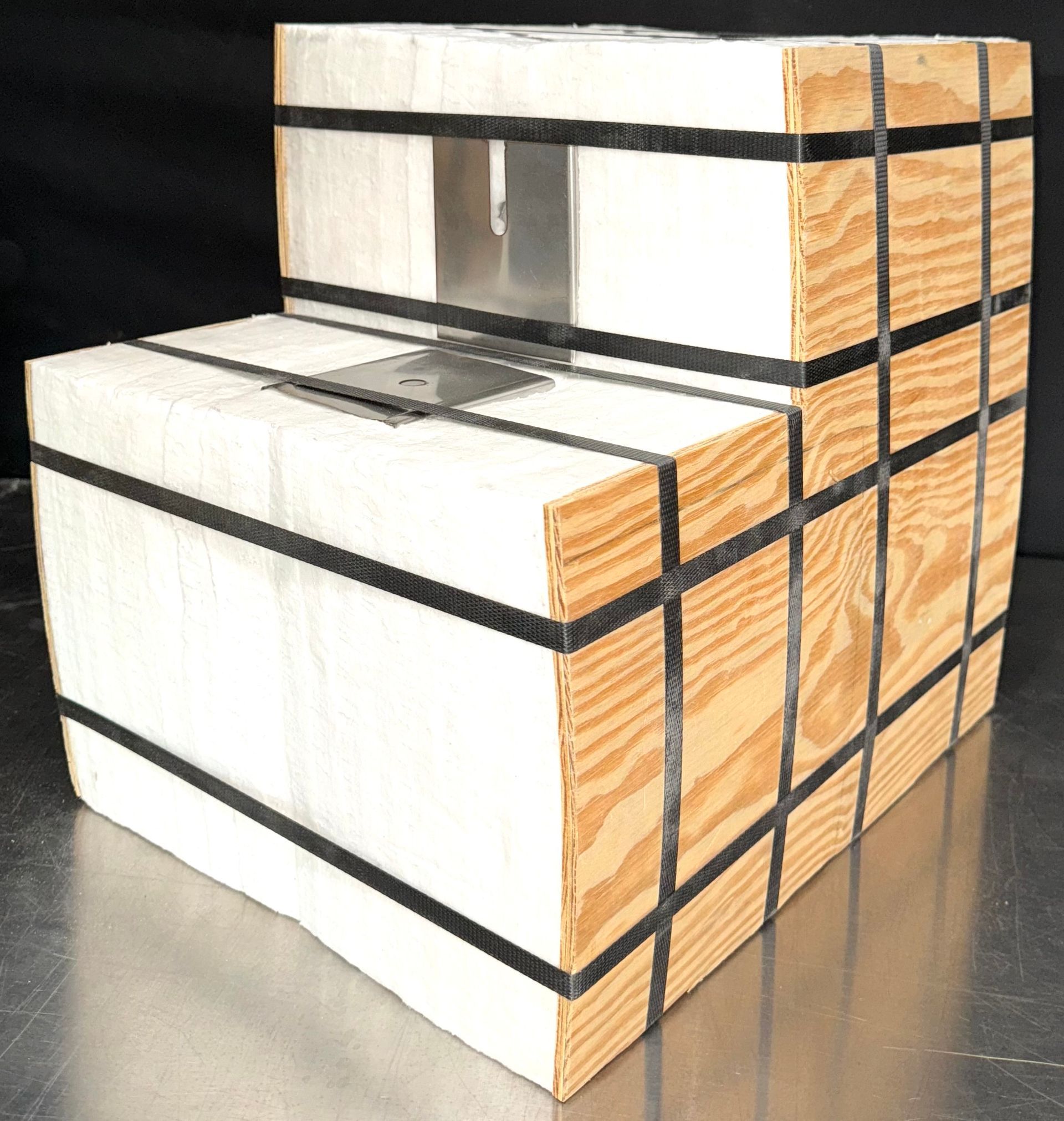

A wedge module is a type of ceramic fiber insulation module designed with a tapered, wedge-shaped form. These modules are typically used in high-temperature insulation applications where there is a need for precise fitting and space optimization.

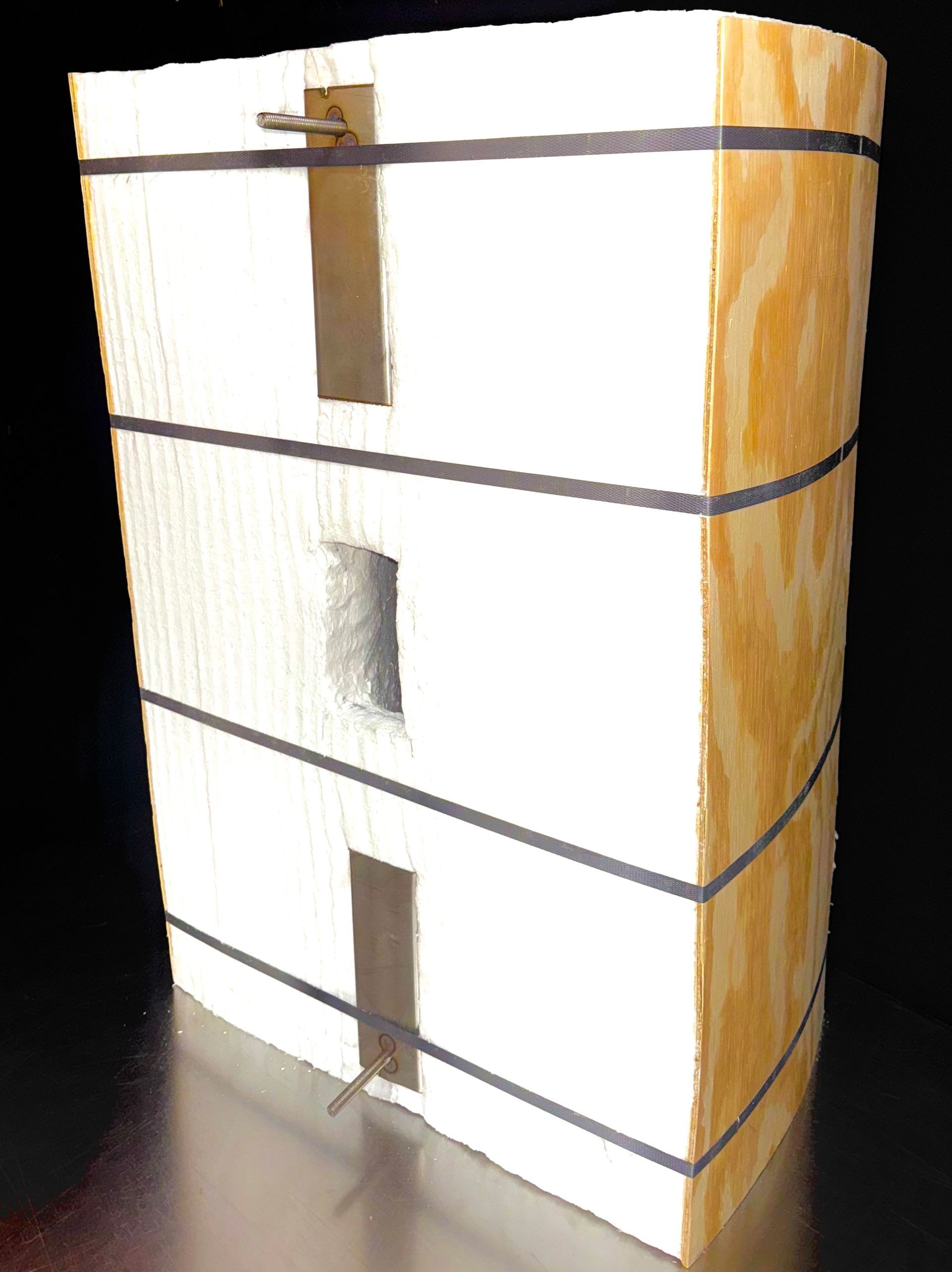

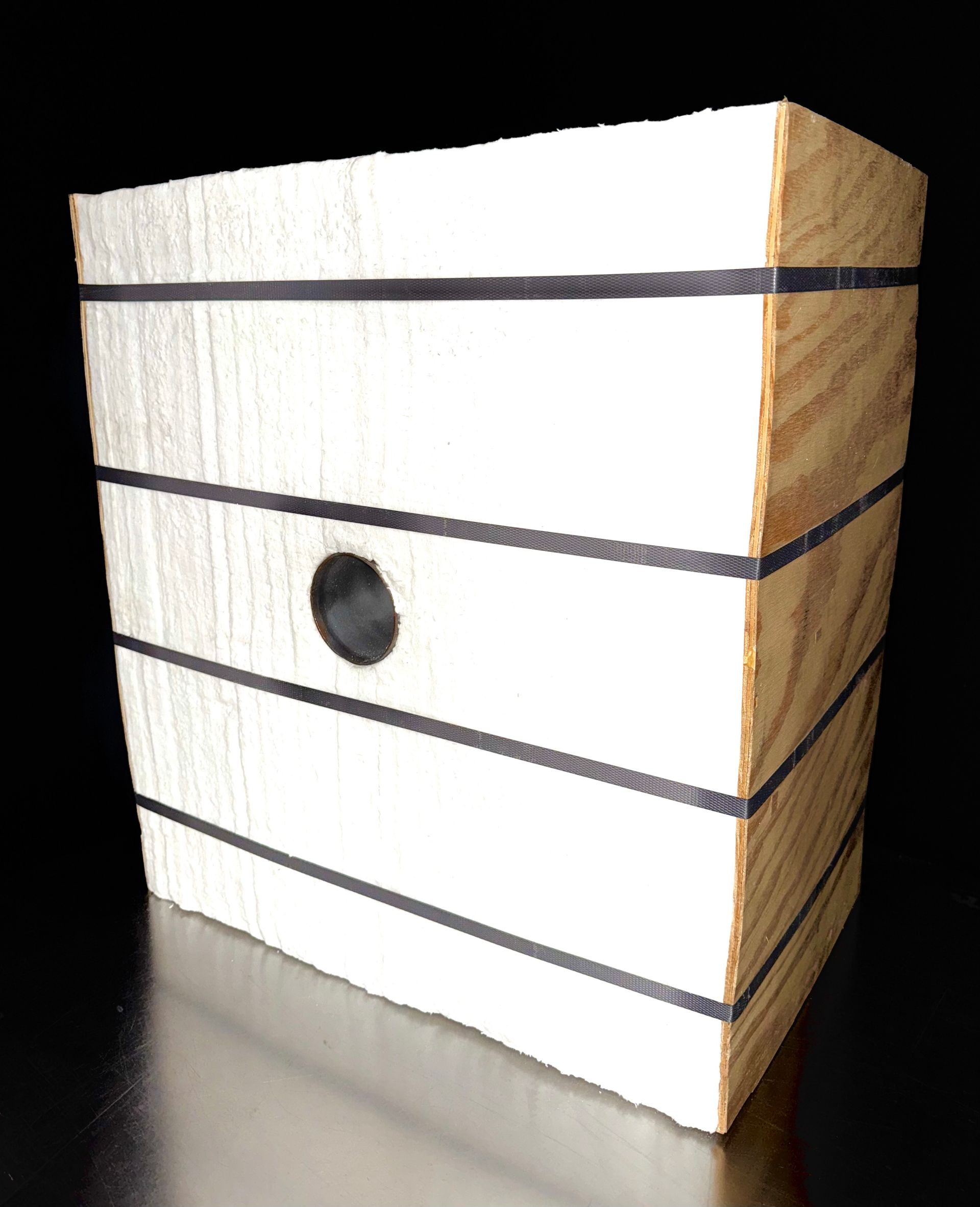

A peepsite module is a type of ceramic fiber insulation module that is specifically designed to cover or seal peep sights (small viewing windows). The term "peepsite" refers to these observation ports that allow operators to visually inspect the interior of high-temperature environments without opening the structure or compromising the temperature regulation.

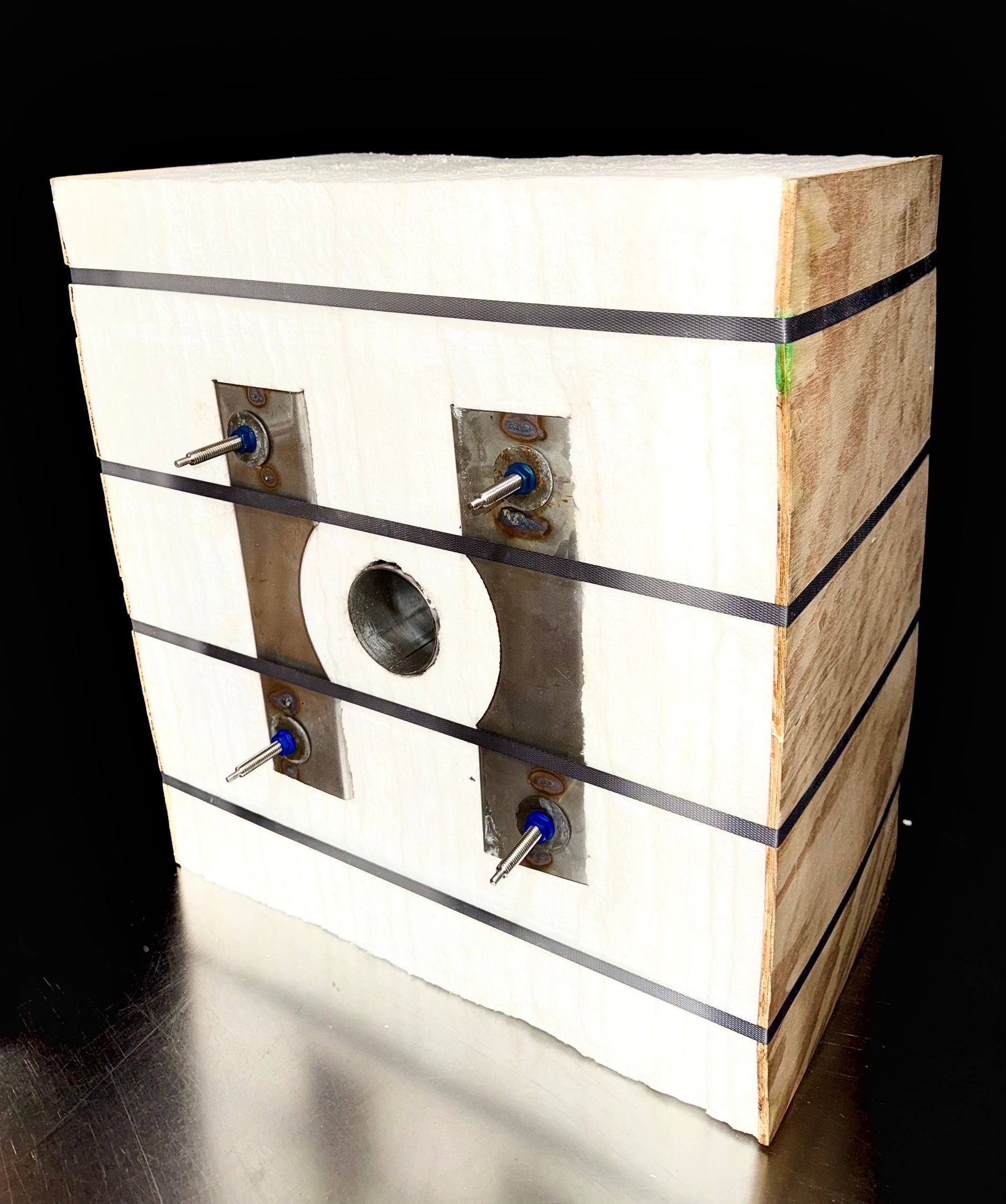

A burner block module is a type of ceramic fiber insulation module specifically designed for use around burners or combustion areas. These modules are shaped to fit around burner zones. Protecting surrounding components from temperature and heat damage.

These modules are typically used for furnace doors and places where less joints in the module lining are desired.

Nature's Symphony

Monolithic Bloc's are composed of (2) blown halves of ceramic fiber, opposed to our Texstack or Texfold where we are combining layers.

Ceramic Fiber Modules FAQ

Q. What Are Ceramic Fiber Modules, and How Do They Improve Industrial Insulation Performance?

A. Ceramic fiber modules are rigid, pre-formed insulation units made from high-temperature-resistant ceramic fiber materials. They provide reliable thermal protection in furnaces, kilns, and boilers by minimizing heat loss and shielding structural components. These modules are engineered for durability under extreme thermal cycling, making ceramic fiber products in Houston, TX, essential for industrial efficiency and safety.

Q. What Types of Ceramic Fiber Products Does Applied Refractory Offer for Complex Installations?

A. Applied Refractory manufactures a full range of specialized modules, including bullnose, wedge, peepsite, burner block, and Monolithic Blocs. Each is designed for precise fit and maximum performance in challenging environments. Whether you need curved-edge solutions or tapered joint fills, our ceramic fiber products ensure complete coverage and long-term integrity in high-heat applications.

Q. How Do Monolithic Blocs Differ From Standard Ceramic Fiber Products?

A. A. Monolithic Blocs are constructed from two blown ceramic fiber halves fused together, offering higher density and fewer internal joints than Texfold or Texstack modules. This design enhances structural strength and reduces fiber erosion in high-wear areas like furnace doors. For superior durability and performance, trust Applied Refractory’s advanced ceramic fiber products in Houston, TX. Call (936) 776-4070 today for expert guidance.

Q. Why Choose Applied Refractory for Ceramic Fiber Products in Industrial Settings?

A. Applied Refractory delivers engineered ceramic fiber products built to withstand the most demanding thermal conditions. With precision manufacturing and a deep understanding of industrial needs, we provide reliable, long-lasting insulation solutions. Our expertise in ceramic fiber in Houston, TX, applications ensures optimal fit, performance, and energy efficiency for your high-temperature systems.

Q. Can Ceramic Fiber Modules Be Customized for Unique Furnace Geometries?

A. Yes, Applied Refractory offers custom-designed ceramic fiber modules to meet specific dimensional and thermal requirements. Whether it’s non-standard shapes, tight clearances, or complex curves, our team fabricates solutions that integrate seamlessly. As a leading provider of ceramic fiber solutions, we ensure every module supports peak operational reliability and safety.